Mam Ba Crimp Screen Cloths Mesh

Mam Ba are able to deliver options of woven wire weave styles to

perfectly suit your filtration and separation applications

,

such as:

plain weave (double crimp),

The advantages of plain weave woven wire mesh are simplicity and

high weave precision. This type of weave is used where the opening

is relatively small, can guarantee achieving high efficiency and

sustained performance screening.

lock crimp weave,

In the lock crimp weave type, weft and warp wires pass each other

and get locked together at the point of intersection. The crimping

is done to lock the wires to prevent from abrasion caused by wire

movements. This weave type works perfectly for screening

applications where the aperture size and wire diameter are

relatively large.

flat top weave

The flat top weave offers a smooth surface for easier material

flow. This type of woven wire provides long abrasion resistance

lifetime since there are no obstacles on the smooth surface side to

strike the material during its flowing.

intercrimp weave

Intermediate crimp, or simply intercrimp has extra crimps in warp

and weft wires between the intersections, it is primarily used

where larger aperture size is required while the wire diameter

remains stable. The rigidity and stability are greater than common

woven wire screen.Thanks to its feature of large open area, the

intercrimp woven wire screen is ideally suited for use in

applications with high throughput.

Mainly Material:highly abrasion-resistant spring steel wire or

stainless spring steel wire.

1.Carbon Steel Wire Parameter:

| No | Grade | Chemical Composition |

| C | Si | Mn |

| 1 | 45 | 0.42-0.50 | 0.17-0.37 | 0.50-0.80 |

| 2 | 50 | 0.47-0.55 |

| 3 | 55 | 0.52-0.60 |

| 4 | 60 | 0.57-0.65 |

| 5 | 65 | 0.62-0.70 |

| 6 | 70 | 0.67-0.75 |

| 7 | 65Mn | 0.62-0.70 | 0.90-1.20 |

| 8 | 72A | 0.70-0.75 | 0.15-0.35 | 0.30-0.60 |

2.Stainless Steel Wire Paramter:

| No | Grade | Chemical Composition |

| C | Ni | Mn | Cr |

| 1 | 304 | ≤0.08 | 8.0-11.0 | ≤2 | 18.0-20.0 |

| 2 | 321 | ≤0.08 | 9.0-12.0 | ≤2 | 17.0-19.0 |

| 3 | 316 | ≤0.08 | 10.0-14.0 | ≤2 | 16.0-18.5 |

| 4 | 2205 | ≤0.03 | 4.5-6.5 | 2.5-3.5 | 21.0-24.0 |

| 5 | 2507 | ≤0.03 | 6-8 | ≤1.2 | 24-26 |

Opening size:

1 - 152.4 mm

Wire diameter:

0.5 - 19.05mm

Hole type: square, rectangular and long slot.

Supplied dimensions:

as required by customer.Rolls or Cut to Flat Plate

Aperture, Wire Diameter and Diagonal Error or Tolerance:

1. Aperture error: ≤3%,which is better than International

Standards;

2. Wire diameter error: ±3%;

3. Diagonal error: ≤9mm every 2m;

It ensures every piece of wire cloth we made can be etching with

remarkable sign of Mam Ba: square, flatness and right tightness.

The Woven Wire Screens are manufactured with an industry-leading stringent wire opening

of ±3% and extremely tight crimps and weave for a longer wear life

and the elimination of premature failure.

Twin Wire Screen Mesh The Benefits Are Clear

1. Handles high-impact loads & wears better than heavier

single-strand wire

2.Excels with large feed materials

3. Reduces screen cloth change-outs & production costs per ton

4. Improves material throughput by up to 50% with more open area

than perforated punch plate

5. Increases the volume of material you can process

6. Reduces installation time because the two lighter-weight wires

bend easier than one heavy wire

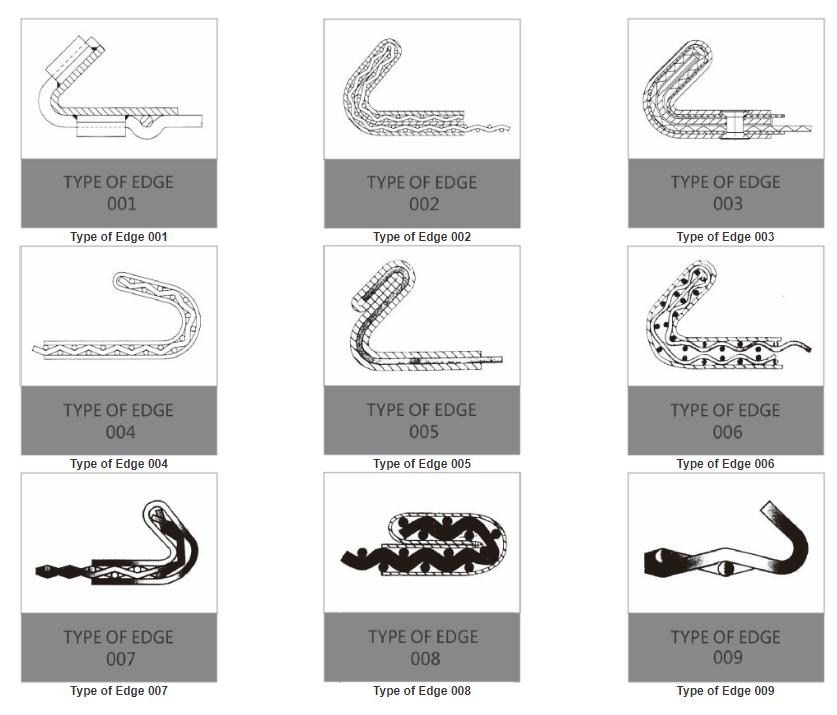

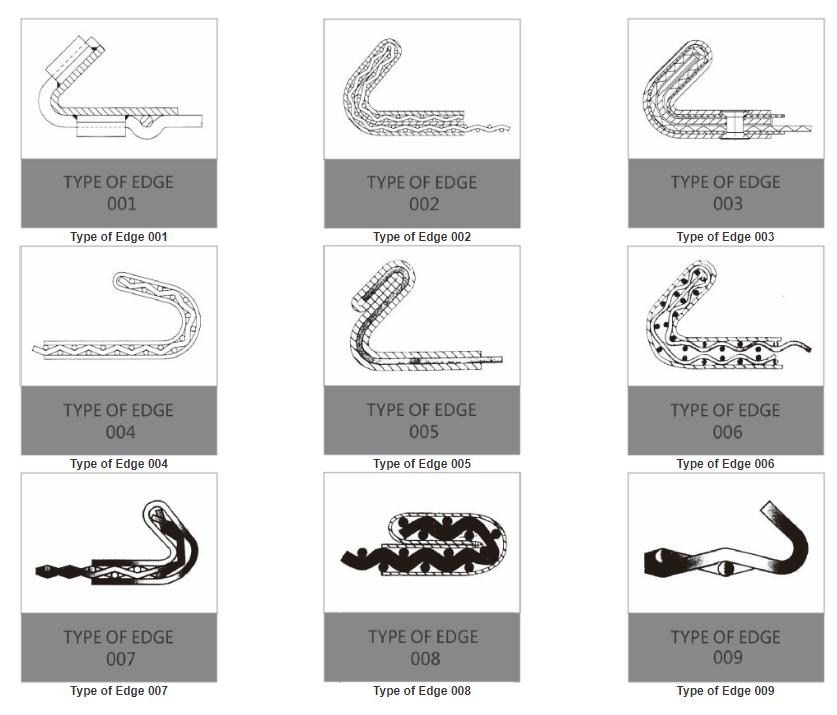

Edge Types:

Weaving Type:

Screen Cloths Mesh 5 Main Applications:

1. Sand Aggregate (Quarries)

2. Mining Companies & Mining Machinery

3. Road Construction Companies & Road machinery

4. Hot Mix Asphalt (HMA) Plants

5. Construction materials recycle

Mam Ba Wear Resistance Metal Wire Mesh Screensused Cases: