Mam Ba Wire Mesh MFG Company:

Mam Ba Wire Mesh MFG Company’s strict quality control system starts

at the very beginning: selecting the right material. There are more

than 500 steel works in China. We only chose 2 of them as our

material suppliers. Except their stable quality (and good

qualification we need), they must be able to customize steel wire

rods in accordance with correct composition ratios we provide. Most

importantly, they must be able to provide the test report of SGS,

the international third party test organization for every batch of

steel wire rods they produced.

Then these steel wire rods, the most suitable material for wire

cloth, will be sent to China Juli Group. As our long-term partner,

Juli Group, the biggest Sling manufacturer in the world, owns the

most advanced wire drawing and heat treatment technique. Here,

wires are taking lead patenting process to change their basic micro

structure and texture to gain more fine grained pear lite. It is a

necessary step to make sure our woven wire cloth features high

tensile strength and better ductility.

Now, the material stage is ready. The wires will face one more test

after they enter our factory. Our Quality Supervision Department

will check its tensile strength, diameter and wire surface to

decide if it can meet out company own standard which is actually

higher than our National Standards..

The Woven Wire Screens are manufactured with an industry-leading stringent wire opening

of ±3% and extremely tight crimps and weave for a longer wear life

and the elimination of premature failure.

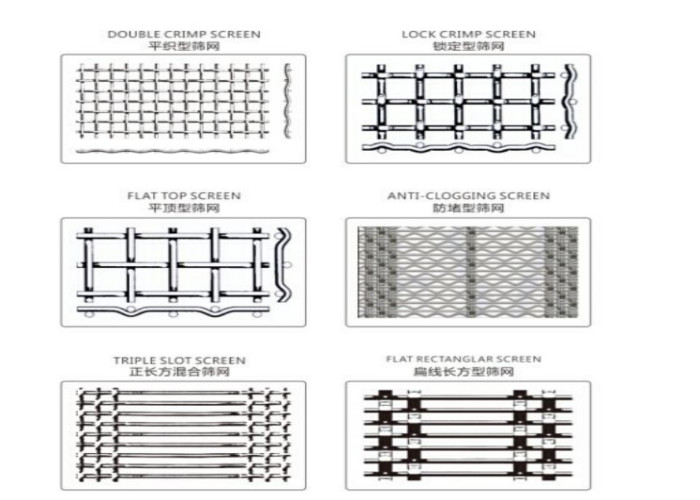

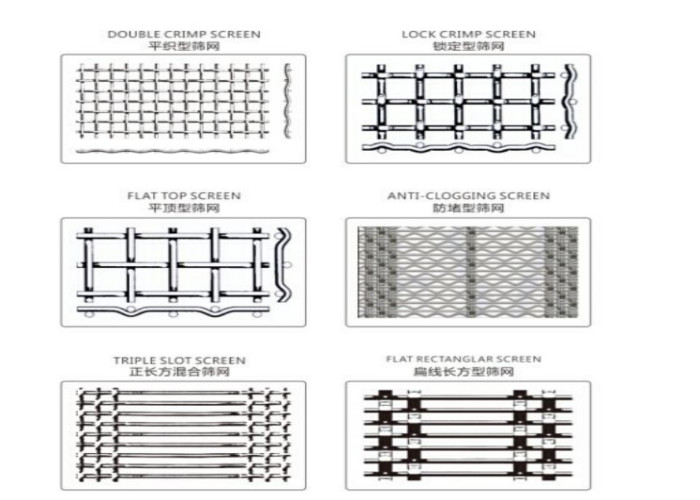

Weave Types

Material:

Mainly Material:highly abrasion-resistant spring steel wire or

stainless spring steel wire.

Corrosion, abrasion, heat, vibration and weight are important

factors to consider when choosing the metal or alloys to use to

manufacture a screen

We specialize in screens woven from high carbon, high tensile

spring steel, (unsurpassed for durability and long life with heavy

abrasive material) and stainless steel which resists heat and

corrosion giving longer life and durability.

Carbon Steel Wire Parameter:

| No | Grade | Chemical Composition |

| C | Si | Mn |

| 1 | 45 | 0.42-0.50 | 0.17-0.37 | 0.50-0.80 |

| 2 | 50 | 0.47-0.55 |

| 3 | 55 | 0.52-0.60 |

| 4 | 60 | 0.57-0.65 |

| 5 | 65 | 0.62-0.70 |

| 6 | 70 | 0.67-0.75 |

| 7 | 65Mn | 0.62-0.70 | 0.90-1.20 |

| 8 | 72A | 0.70-0.75 | 0.15-0.35 | 0.30-0.60 |

Stainless Steel Wire Paramter:

| No | Grade | Chemical Composition |

| C | Ni | Mn | Cr |

| 1 | 304 | ≤0.08 | 8.0-11.0 | ≤2 | 18.0-20.0 |

| 2 | 321 | ≤0.08 | 9.0-12.0 | ≤2 | 17.0-19.0 |

| 3 | 316 | ≤0.08 | 10.0-14.0 | ≤2 | 16.0-18.5 |

| 4 | 2205 | ≤0.03 | 4.5-6.5 | 2.5-3.5 | 21.0-24.0 |

| 5 | 2507 | ≤0.03 | 6-8 | ≤1.2 | 24-26 |

Opening size:

1 - 152.4 mm

Wire diameter:

0.5 - 19.05mm

Hole type: square, rectangular and long slot.

Supplied dimensions:

as required by customer.Rolls or Cut to Flat Plate

Aperture, Wire Diameter and Diagonal Error or Tolerance:

1.Aperture error: ≤3%,which is better than International Standards;

2.Wire diameter error: ±3%;

3.Diagonal error: ≤9mm every 2m;

It ensures every piece of wire cloth we made can be etching with

remarkable sign of Mam Ba: square, flatness and right tightness.

Edge Types:

Our hook making adopts the electromagnetic coil heating process.

All hooks are one-time forming. There are different type of hooks

and edges available.

We can provide wire cloth with or without hooks and wire cloth

rolls in different size according to client’s requests.

Hook and Edge

1.Our hook making adopts the electromagnetic coil heating process.

All hooks are one-time forming. There are different type of hooks

and edges available.

2.We can provide wire cloth with or without hooks and wire cloth

rolls in different size according to client’s requests.

Features:

Easy to Install

Lower Cost

Higher screening accuracy

Require less maintenance

Sturdy construction

Installation instructions:

the screen is installed with using of tensioning metallic bars into

a separator over different types of hook strips, further with using

of side bars and wedges, possibly is fastened into a frame.

Application:

applies to vibrating screens for primary sieving of mine and

aggregates, as well as asphalt mixer plant in road building.