High Durability Crimp Spring Screen for Sieving, Filtering, and

Separation Processes

CRIMP SPRING SCREEN IS A MAIN ELEMENT OF VIBRATING SCREENS USED FOR

CLASSIFICATION AND DRAIN PRODUCTS IN PROCESSING PLANTS OF

MINERALPRODUCTS. THEY CAN BE USED IN DIFFERENT AREAS OF ECONOMY TO

SCREEN LOOSE

MATERIALS REQUIRED GRAIN SIZE CLASSIFICATION.

WE OFFER CRIMPED SCREENS IN SHEETS AS WELL AS ROLLS. WE ALSO OFFER

A VERSION OF SCREENS WITH HOOK FOR CROSSWISE AND LENGTHWISE

TENSIONING. SCREENS ARE MADE OF MATERIALS SUCH AS: CARBON STEEL AND

HIGH STRENGTH

ALLOYS, STAINLESS, ACID – PROOF, HEAT-RESISTANT MATERIALS, ETC.

Crimp wire mesh screens are a specific type of woven wire mesh

characterized by their crimped wire design. This unique

construction enhances their strength and stability, making them

suitable for a wide range of applications. Here’s an overview:

Key Features

Crimped Structure: The wires are crimped before weaving, which

creates a more robust and stable mesh. This design helps maintain

the shape under tension and load.

Increased Strength: The crimped wires provide added rigidity and

durability, making them ideal for heavy-duty applications.

Versatile Mesh Sizes: Available in various mesh sizes and wire

diameters, allowing for customization depending on specific needs.

Effective Filtration: The design allows for efficient filtering and

separation of materials, making it suitable for various industrial

processes.

Variety of Materials: Typically made from stainless steel, carbon

steel, or other alloys, offering options for different

environmental conditions.

Applications

Mining and Quarrying: Used for screening aggregates, ores, and

other materials, where strength and durability are critical.

Construction: Employed for reinforcing concrete and as protective

barriers for job sites.

Agriculture: Utilized in processing and grading agricultural

products, such as grains and seeds.

Food Processing: Used for sifting and filtering in the production

of food products, ensuring compliance with hygiene standards.

Waste Management: Effective for separating solids from liquids in

various waste treatment processes.

Types of Crimp Wire Mesh Screens

Single Crimp: Each wire is crimped at regular intervals, creating a

straightforward mesh pattern.

Double Crimp: Features additional crimping for enhanced strength

and stability, suitable for heavier applications.

Intermediate Crimp: A combination of single and double crimping,

providing a balance between flexibility and strength.

Considerations

When selecting crimp wire mesh screens, consider the following:

Mesh Size and Opening: Choose based on the specific filtration or

separation needs of your application.

Wire Diameter: Thicker wires increase strength but can reduce the

mesh's flexibility.

Material Selection: Ensure the material is appropriate for the

environment, especially regarding corrosion resistance.

Installation Requirements: Consider how the screens will be

installed and whether they need to be custom-cut or shaped.

Woven wire screen cloths Material:

highly abrasion-resistant spring steel wire or stainless spring

steel wire.

| No | Grade | Chemical Composition |

| C | Si | Mn |

| 1 | 45 | 0.42-0.50 | 0.17-0.37 | 0.50-0.80 |

| 2 | 50 | 0.47-0.55 |

| 3 | 55 | 0.52-0.60 |

| 4 | 60 | 0.57-0.65 |

| 5 | 65 | 0.62-0.70 |

| 6 | 70 | 0.67-0.75 |

| 7 | 65Mn | 0.62-0.70 | 0.90-1.20 |

| 8 | 72A | 0.70-0.75 | 0.15-0.35 | 0.30-0.60 |

| No | Grade | Chemical Composition |

| C | Ni | Mn | Cr |

| 1 | 304 | ≤0.08 | 8.0-11.0 | ≤2 | 18.0-20.0 |

| 2 | 321 | ≤0.08 | 9.0-12.0 | ≤2 | 17.0-19.0 |

| 3 | 316 | ≤0.08 | 10.0-14.0 | ≤2 | 16.0-18.5 |

| 4 | 2205 | ≤0.03 | 4.5-6.5 | 2.5-3.5 | 21.0-24.0 |

| 5 | 2507 | ≤0.03 | 6-8 | ≤1.2 | 24-26 |

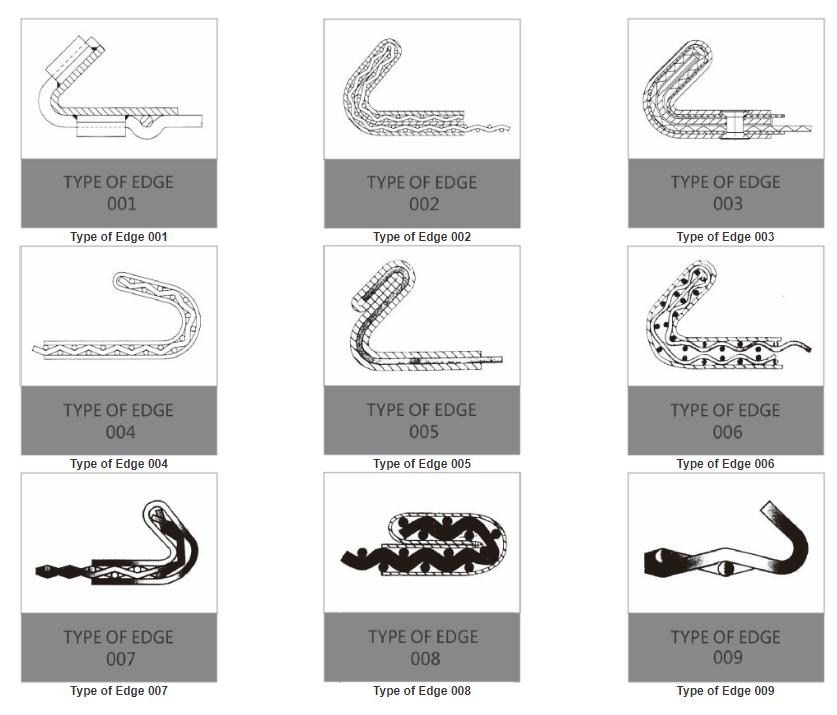

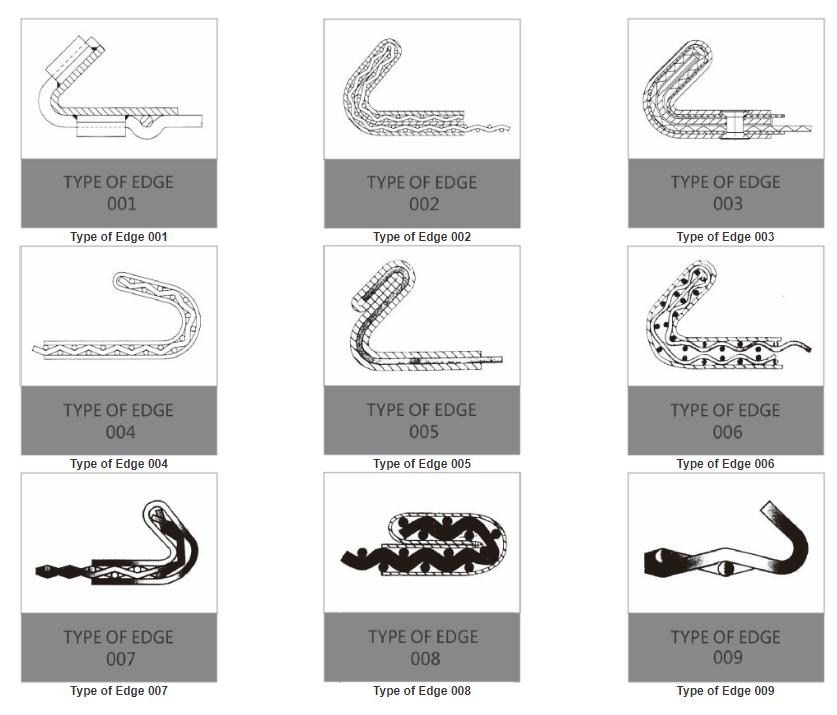

Woven wire screen cloths Edge Types:

Woven wire screen cloths Aperture and Wire Diameter:

| Opening (Aperture) | Wire Diameter | Open Area % | Approx. Weight kg/m2 |

| mm | inch | mm | inch |

| 25.4 | 1 | 5.72 | 0.225 | 66.62% | 13.3 |

| 28.58 | 1 1/8 | 5.72 | 0.225 | 69.43% | 12.2 |

| 31.75 | 1 1/4 | 5.72 | 0.225 | 71.80% | 10.9 |

| 19.05 | 3/4 | 6.17 | 0.243 | 57.06% | 19.1 |

| 20 | 48/61 | 6.17 | 0.243 | 58.41% | 18.6 |

| 22.23 | 7/8 | 6.17 | 0.243 | 61.27% | 17.3 |

| 25.4 | 1 | 6.17 | 0.243 | 64.73% | 15.4 |

| 26.99 | 1 1/16 | 6.17 | 0.243 | 66.25% | 14.6 |

| 28.58 | 1 1/8 | 6.17 | 0.243 | 67.64% | 13.8 |

| 31.75 | 1 1/4 | 6.17 | 0.243 | 70.11% | 12.6 |

| 25.4 | 1 | 7.19 | 0.283 | 60.74% | 19.8 |

| 28.58 | 1 1/8 | 7.19 | 0.283 | 63.84% | 18.2 |

| 31.75 | 1 1/4 | 7.19 | 0.283 | 66.48% | 16.7 |

| 38.1 | 1 1/2 | 7.19 | 0.283 | 70.77% | 14.5 |

| 25.4 | 1 | 7.92 | 0.312 | 58.11% | 24 |

| 28.58 | 1 1/8 | 7.92 | 0.312 | 61.31% | 22 |

| 31.75 | 1 1/4 | 7.92 | 0.312 | 64.06% | 20.25 |

| 38.1 | 1 1/2 | 7.92 | 0.312 | 68.54% | 17.5 |

| 41.28 | 1 5/8 | 7.92 | 0.312 | 70.40% | 16 |

| 44.45 | 1 3/4 | 7.92 | 0.312 | 72.04% | 15 |

| 50.8 | 2 | 7.92 | 0.312 | 74.84% | 13.5 |

| 25.4 | 1 | 9.19 | 0.362 | 53.92% | 30.9 |

| 31.75 | 1 1/4 | 9.19 | 0.362 | 60.14% | 26 |

| 38.1 | 1 1/2 | 9.19 | 0.362 | 64.91% | 21.4 |

| 41.28 | 1 5/8 | 9.19 | 0.362 | 66.90% | 22.4 |

| 44.45 | 1 3/4 | 9.19 | 0.362 | 68.67% | 20 |

| 50.8 | 2 | 9.19 | 0.362 | 71.71% | 18.1 |

| 57.15 | 2 1/4 | 9.19 | 0.362 | 74.21% | 16.2 |

| 63.5 | 2 1/2 | 9.19 | 0.362 | 76.31% | 14.85 |

| 50.8 | 2 | 11.1 | 0.437 | 67.35% | 25.3 |

| 50.8 | 2 | 12.7 | 0.5 | 64.00% | 32.3 |

| 57.15 | 2 1/4 | 12.7 | 0.5 | 66.94% | 29.53 |

| 63.5 | 2 1/2 | 12.7 | 0.5 | 69.44% | 26.5 |

| 76.2 | 3 | 12.7 | 0.5 | 73.47% | 22.7 |

| 88.9 | 3 1/2 | 12.7 | 0.5 | 76.56% | 20.2 |

| 101.6 | 4 | 12.7 | 0.5 | 79.01% | 17.9 |

Applications

- Classification: Used for grain size classification in various sectors of the

economy.

- Loose Material Screening: Effective in screening loose materials across different

industries.

Product Offerings

- Forms Available: Offered in sheets and rolls.

- Tensioning Options: Available with hooks for crosswise and lengthwise tensioning,

enhancing stability and performance.

Material Composition

Crimp screens are made from a variety of materials, including:

- Carbon Steel: For general applications.

- High-Strength Alloys: For enhanced durability.

- Stainless Steel: For corrosion resistance.

- Acid-Proof Materials: Suitable for harsh chemical environments.

- Heat-Resistant Materials: Designed for high-temperature applications.

Advantages

- Durability: Resistant to wear and tear.

- Versatility: Suitable for various industries and applications.

- Efficiency: Optimizes the classification process for better productivity.